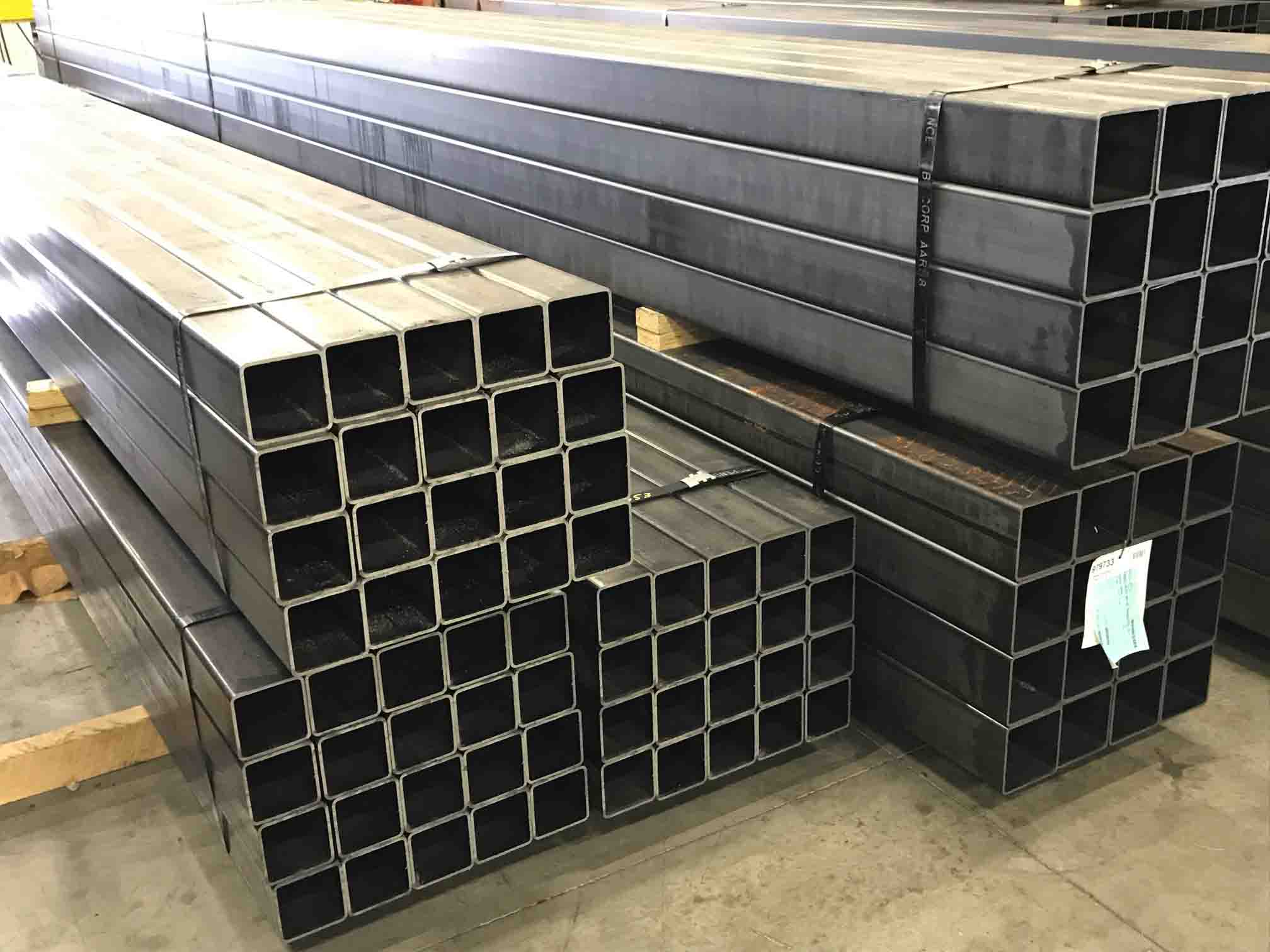

Materials Used

We manufacture components and assemblies in a wide range of materials including various carbon grades of plate (A36, A572, Grade 50, 1015 and C1045 among others), manganese steel, stainless steel, aluminum and high alloy steel (including AR400). We also process components from tube stock, angle, channel, pipe and bar as well as castings and forgings.

Capabilities

Our in-house material handling, cutting, forming, welding, and machining services, together with our extensive network of local service providers allows us to offer our customers turn-key solutions for their component needs. We often work with customers throughout the design stage to help eliminate cost in the final product.

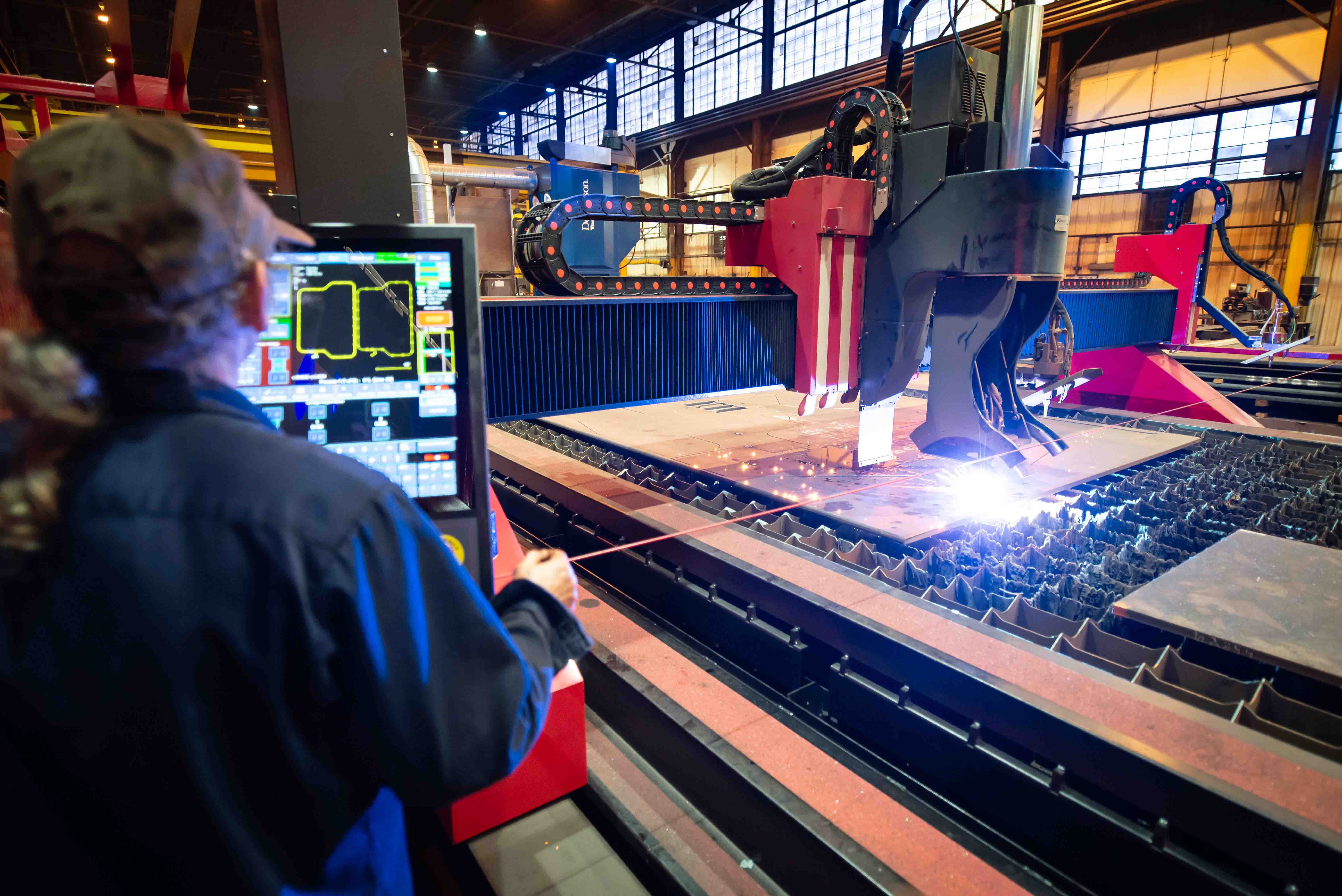

CNC PLATE CUTTING WITH CONTOUR BEVELING

Kinetic K2500 Plate Burning Machine

(2) Oxy-Acetylene Torches

(1) Plasma Torch (400 Amp Hypertherm)

- CNC-Controlled Contour Beveling

Maximum Plate Size : 120” wide x 480” long

Maximum Plate Thickness: Up to 2” (Plasma) and Up to 8” (Oxy)

C & G Systems with Burny Phantom CNC Control

(1) Oxy-Acetylene Head

(1) Plasma Head

Maximum Plate Size: 96" x 180"

Maximum Plate Thickness: 12"

CNC PLASMA PUNCH & MARKING

Whitney 3400 RTC Fabricating Center

Plasma Cutting to 1/2" Thick

Punching to 1/2" Thick and 5" Diameter

We utilize plasma marking for ease of component location for final weld assembly. This reduces the need for fixtures and layout time.

SAW CUTTING

Horizontal Band Saws with Miter-cut option

Capable of handling material or bundles up to 12” x 12”

Automatic Material Feed

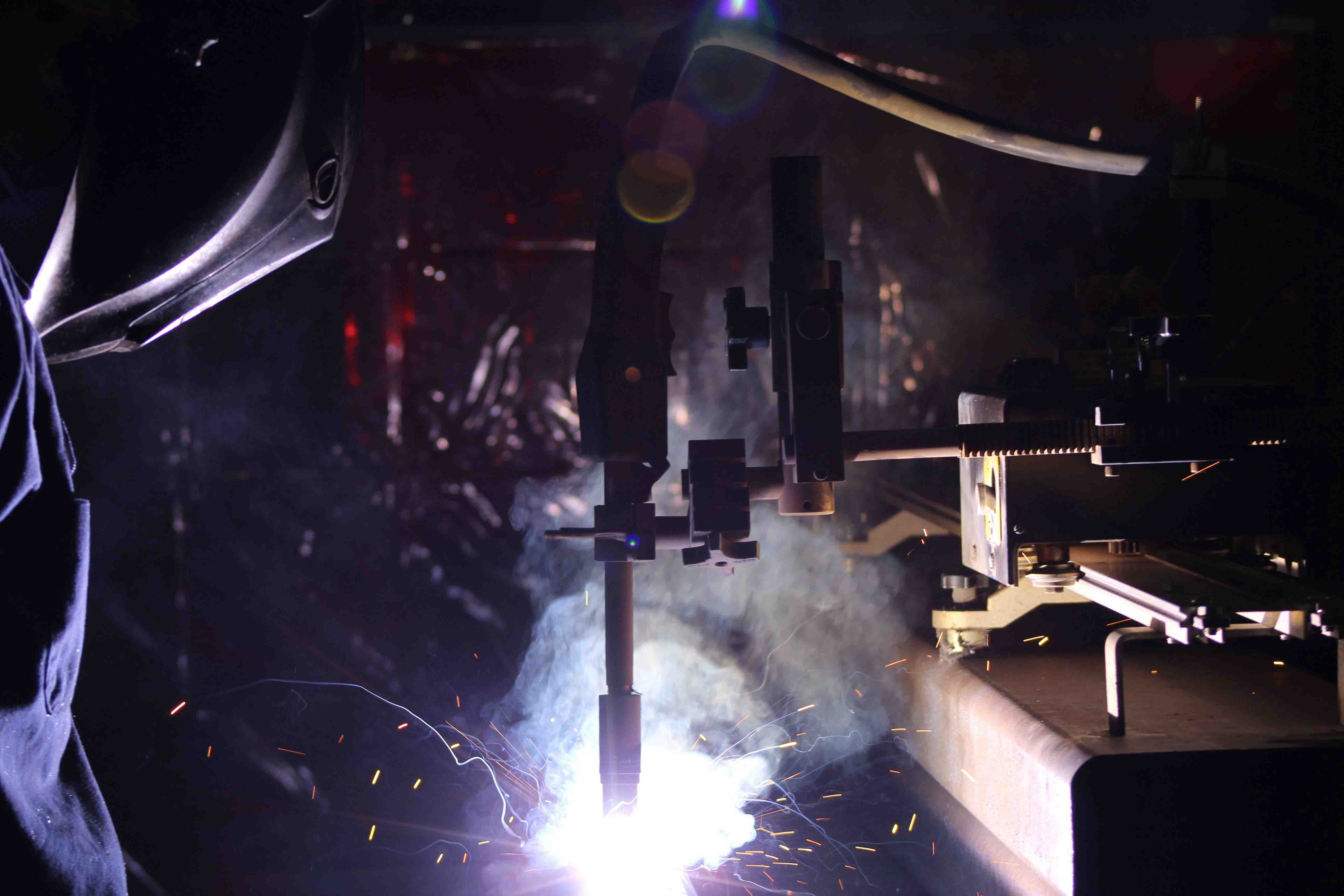

MANUAL AND ROBOTIC WELDING

Fabricated Metal Products is certified to perform high quality welding to the highest of standards such as AWS D1.1, AWS D1.3, & AWS D1.5 and also welding of aluminum, stainless, manganese, along with hard-facing/carbide overlay when customer needs require.

MIG and TIG Welding

Robotic and Automated Welding

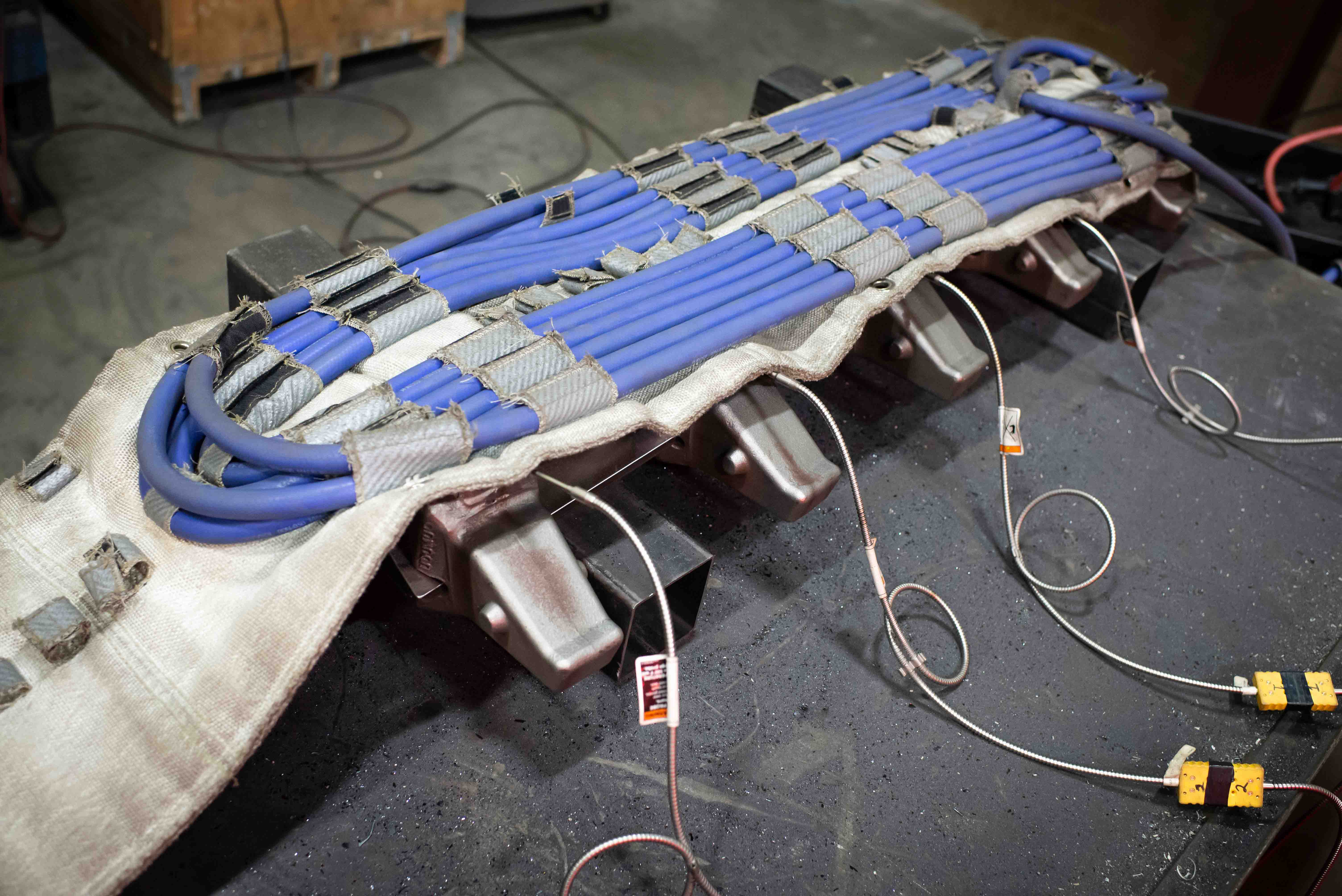

HARDFACE, MANGANESE, AND WARM WELDING

FORMING, FORGING, and ROLLING

Forming

Cincinnati Press Brake

600 ton maximum

Bed width 192" maximum

Hot Forging

Clearing 3000 Ton Press

Maximum Ram Pressure 3000 Tons

50" Ram / 37.75" Stroke

Ram Size 56" x 56"

Induction Heating to 2000 degrees

HPM 500 Ton Hydraulic Press

Maximum Ram Pressure 500 tons

Plate Rolling

Using our plate rolls (Bertsch and Wysong & Miles) we can roll steel cylinders from plates

Maximum Width: 144"

Maximum Thickness: 5/8"

Diameters from 8" to 144"

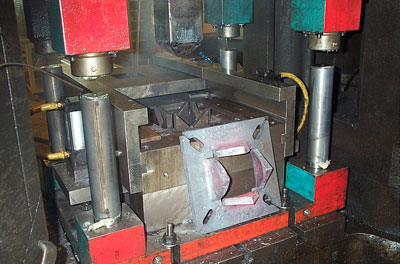

CNC MACHINING & INSPECTION

CNC MACHINING & MILLING

(5) Viper VMC Machining Centers

35 Horsepower/CAT 50 Holder

120" X by 80" Y by 36" Z Max. Travel Capacity

Fanuc 21I CNC Controllers with Crane Service

Crane Service

TOS – WH105

35 Horsepower

66"X x 60"Y x 54"Z Travels

Table Surface 49" x 55"

Headstock Vertical 49"; Slide Longitude 49"

PART INSPECTION AND QUALIFICATION

Faro Arm Coordinate Measuring Machine

Measuring Range

Precision to 0.0005" (0.013mm)

7 Axis Availability

Multi-probe Capability (Ball Diameters, Touch Sensitive, Curved and Extension Probes)

Adaptable 3D Measurement Technology

FINISHING AND COATINGS

PAINTING & COATINGS

Utilizing both our in-house capabilities and our external vendors we provide comprehensive solutions to all our customer’s painting requirements and specifications. When customers require additional coatings such as hot dip galvanizing, plating, or powder coating, FMP leverages our strong network of partners to provide a full-service approach to any and all needs.

FINISHING & SURFACE TREAMENTS

FMP also offers blasting of smaller parts and sub-components using internal tumble blast equipment. For large parts and weldments, FMP utilizes our manual blasting booth along with established vendor resources for all parts requiring surface treatments to meet our customers’ needs. If projects call for different media blasting, FMP can provide various services such as sand, glass or other forms of media, to deliver any customer requirement.

HANDLING AND LOGISTICS

FMP offers all shipping options (LTL, Dedicated, Land, Sea, Air, etc) to our customers to make delivery as easy as possible. FMP can handle flatbed loads, utilizing our overhead lifting options or forklifts to get parts on and off the trucks, as well as box-truck loading/unloading, using our loading dock for items requiring this option. With overhead crane lifting capabilities up to 50 ton, as well as fork-trucks to handle smaller lifts and skids, we are ready for ANY part, no matter what the size!

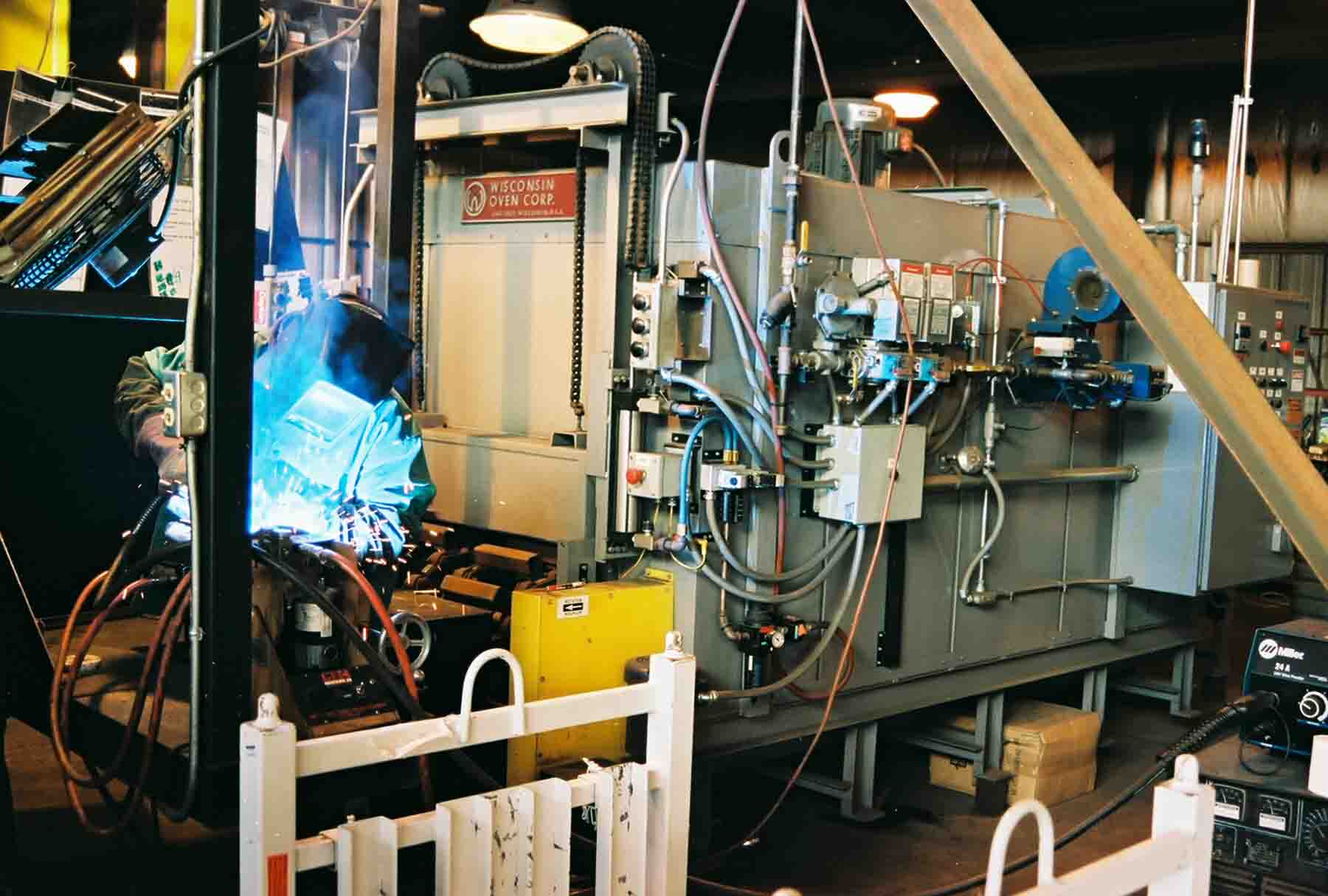

OTHER SERVICES AVAILABLE

Utilizing our internal resources and our network of local suppliers, we can assemble components, provide heat treatment services , manufacture tooling and machining fixtures for internal processing/quality checking and provide managed inventory/stocking programs to name a few. If there is a service you do not see listed, do not hesitate to ask. If we can provide it, FMP will! Our goal is to provide our customers with the best value we can, no matter what the request.

Assembly

After fabricating all of the components, we weld complex assemblies to manufacture finished parts to our customer's specifications.

Heat Treating

Long-standing partnerships with strategic vendors allow FMP to offer a full range of heat treating services including stress relieving, quench and tempering, normalizing, annealing, carburizing, carbon-nitriding, nitriding, and induction hardening, to name a few.

Vendor-Managed and Inventory Stocking Solutions